The towers are available and custom made per order. Due to the volatile situation on the market we can not provide fixed pricing and have to form prices for each order separately.

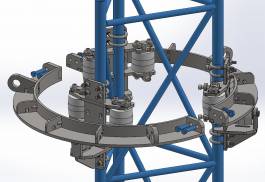

Rings

Weak points of standard solutions

The current market offers rings for rotary towers by multiple manufacturers. The solutions are mostly similar, offering small bearings within the ring that have to withstand the entirety of the force. During the exploitation of such rings over the past 10 years we noticed several major flaws:

1. The small bearings within the ring are prone to corrosion.

2. The small bearings within the ring get destroyed by strong forces caused by winds. This is due to the tower transferring all the force to one, sometimes two bearing. These will inevitably break because of their small dimensions.

3. Once installed the ring cannot be removed from the tower for service. It has to be pulled to the top of the tower and reinstalled in the same manner. This makes the service very difficult and expensive.

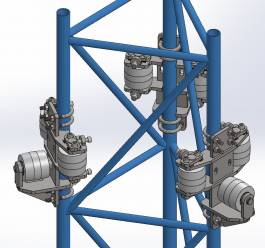

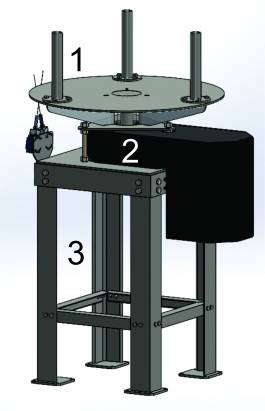

Second generation of open frame rings (OFR)

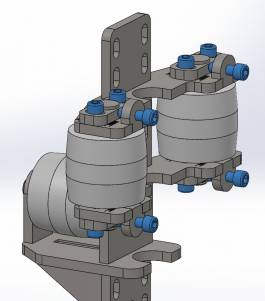

The second generation of open frame rings were developed as a solution to the problems laid out above. The flaws of the small bearing balls described under points 1 and 2 are solved by being replaced with large disks made from hard polymers. Besides not rusting at least two disks take on the tower wind force. They are over sized in dimensions and strength to remain undamaged over long periods of time.

Easy service

When the ring service need arises don’t worry – it’s very simple. The OFR ring is easily lowed to the ground because it consists of two halves and three additional parts with rotating disks are separately mounted to the sides of the tower.

The OFR ring can also be serviced by simply replacing a part because it’s very easy to disassemble and replace.

Better low temperature and winter conditions

The second generation OFR rings perform very well under lower temperatures and ice. The standard rings that have water and oil inside them that will freeze and block the ring making it impossible to turn under such conditions.

Our second generation OFR rings use polymers uses an open design so the ice is accessible and easily shattered and removed.

Optionally, heaters for defrosting can be installed as a feature.

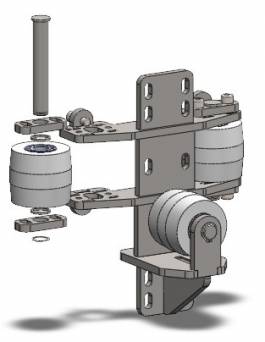

Rotary base

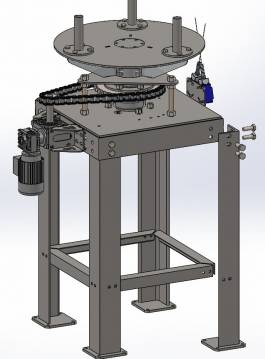

The Motor

Our rotary base comes with a preinstalled motor. You can choose between a single-phase and a three-phase motor.

The motor is separate from the base, making it easy to install and service.

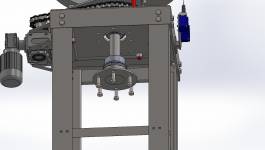

Disconnecting the Engine Box from the Tower

You can unlock the tower to freely rotate with the wind by removing a single bolt from the rotating mechanism. This significantly reduces the risk of antenna damage.

This is a key feature for antenna survival during strong gusts of wind. An unlocked tower offers much lower wind resistance, and the ability to rotate further reduces the strain on your antenna system.

As an example, at the 4O3A station, after installing antennas on a tower equipped with this feature, antenna damage was reduced by 80%!

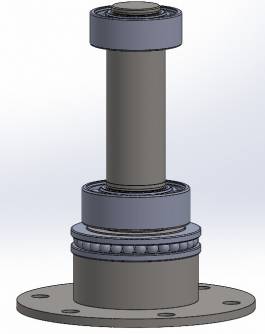

Serviceability and Innovation

The rotary base is engineered with a focus on maintenance and usability — allowing for easy bearing replacement, lubrication, and inspection.

Included with the tower are auxiliary bolts that lock and stabilize the structure, after which the load-bearing section containing the bearings can be effortlessly removed as a separate unit.

This is a major innovation compared to standard tower designs on the market, where bearing service is extremely complicated and labor-intensive.

Once again, 4O3A proves its constant commitment to innovation, delivering the most advanced and practical engineering solution available today.

Moreover, the base is fully disassemblable, making it significantly easier to transport and handle — another thoughtful detail that sets 4O3A apart as a leader in intelligent tower design.

Custom design

In most cases the towers are custom designed by the customer specification. We produce towers of all dimensions.

Prices are generated by request.

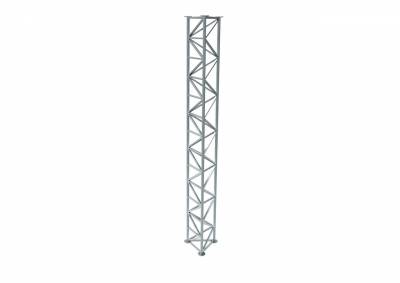

Tower sections

Towers are usually designed with 3m or 6m long sections, with standard width of 50cm, 65cm, 80cm or 100cm. Any other dimensions can be produced on order, and any specific request can be realized.

Height of installed towers worldwide is from 20m to 80m, and it can be taller.

We are producing Self supporting towers as well.

All towers are produced from steel, protected with hot zinc coating.

One section, length 300 cm:

Complete Tower

Some of our towers

• Tower 2 at 4O3A, 36m, rotary

• Rotary tower at ES5TV, 72m high with 8 x 5L15

• MPL tower at 4O3A, 36m, rotary

• Self-supporting tower at 4O3A carrying 2L80, 48m high

Contact us for the configuration and price at . Delivering worldwide.